In the realm of electrical engineering, precision and safety are paramount. One device that plays a crucial role in ensuring both is the Current Transformer (CT). Often overshadowed by more prominent electrical components, CTs are indispensable for accurate measurement and protection in power systems. Without them, monitoring current flow and safeguarding electrical networks would be far more challenging—and far less reliable.

At its core, a CT is a type of instrument transformer designed to step down high currents in electrical circuits to manageable levels. This allows meters, relays, and other instruments to measure and monitor current safely and accurately. Whether in residential, commercial, or industrial settings, CTs ensure that electrical systems operate within safe limits while providing critical data for analysis and decision-making.

How CT Current Transformers Work

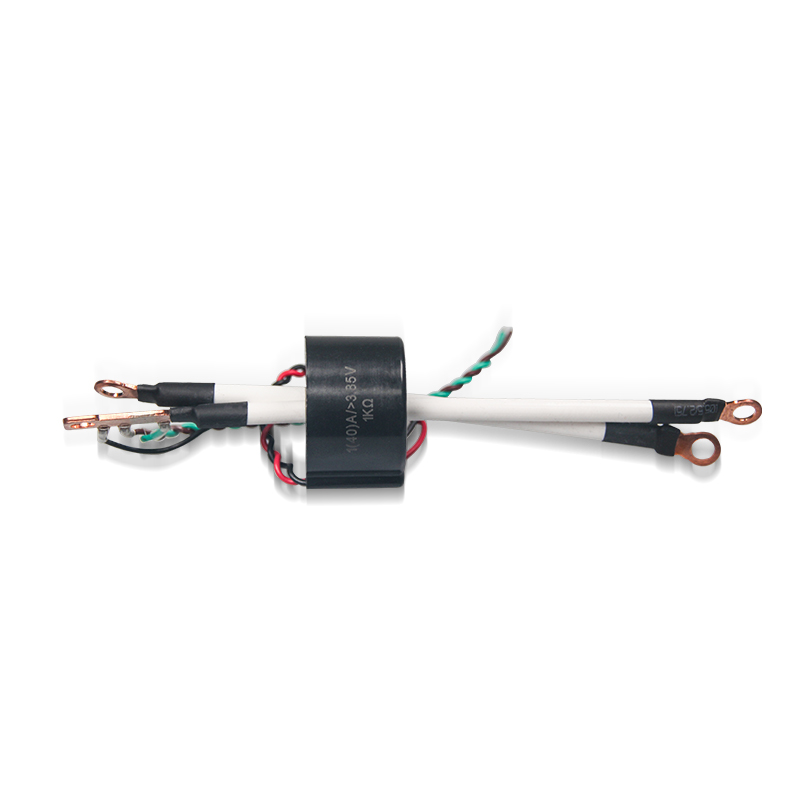

The principle behind a CT is relatively straightforward, yet its implications are profound. A CT consists of a primary winding, a secondary winding, and a magnetic core. The primary winding carries the current from the main circuit, while the secondary winding is connected to measuring or protective devices. When current flows through the primary winding, it generates a magnetic field in the core. This magnetic field induces a proportional current in the secondary winding, which can then be measured or used to trigger protective mechanisms.

One of the key features of CT Current Transformers is their ability to maintain a consistent ratio between the primary and secondary currents. For example, if a CT has a ratio of 1000:5, it means that for every 1000 amps flowing through the primary winding, 5 amps will flow through the secondary winding. This scaling-down process ensures that sensitive instruments can handle the measurements without being damaged by high currents.

Applications of CT Current Transformers

CTs find applications across a wide range of industries and scenarios. In power generation and distribution, they are essential for monitoring load conditions, detecting faults, and protecting equipment from overcurrent situations. Utility companies rely on CTs to ensure that electricity is delivered efficiently and safely to consumers.

In industrial settings, CTs are used to monitor the performance of machinery and equipment. By providing real-time data on current consumption, they help identify inefficiencies, prevent equipment failure, and optimize energy usage. Similarly, in commercial buildings, CTs enable precise energy management, allowing facility managers to track consumption patterns and implement cost-saving measures.

Even in residential environments, CTs play a role. Smart meters, which are becoming increasingly common, often incorporate CTs to measure household electricity usage. This data not only helps consumers understand their energy habits but also enables utilities to implement dynamic pricing models.

Types of CT Current Transformers

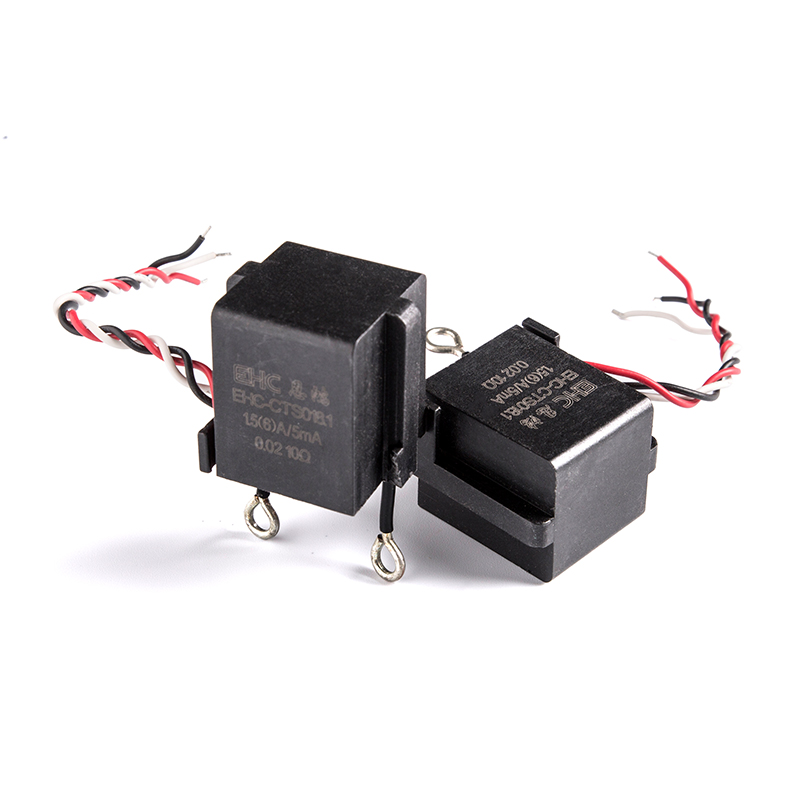

There are several types of CTs, each suited to specific applications. Wound-type CTs have a primary winding with more than one turn and are typically used for lower current applications. Bar-type CTs, on the other hand, use a straight conductor as the primary winding and are ideal for higher current systems.

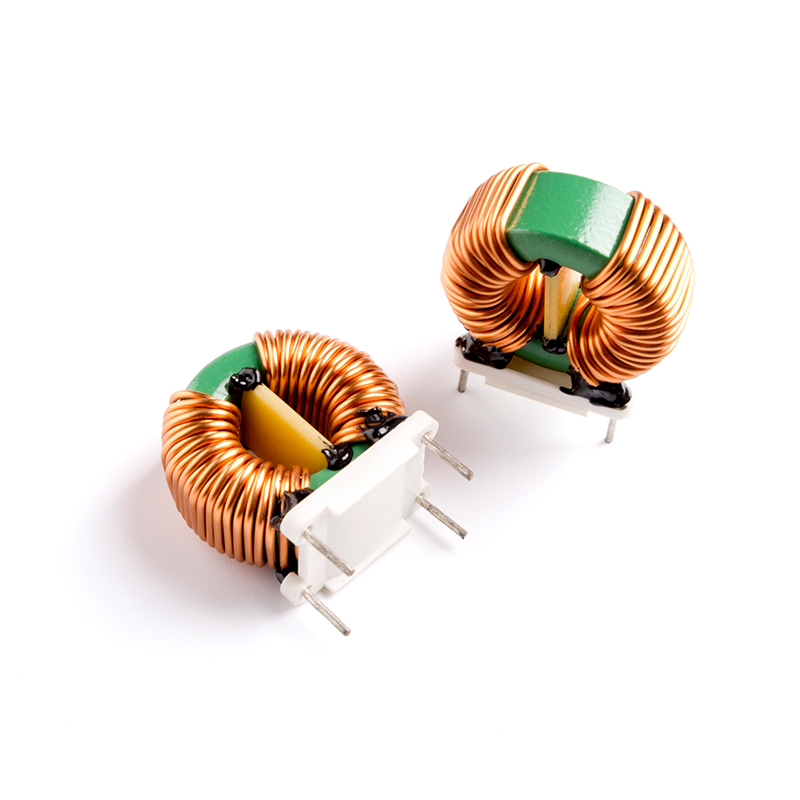

Another popular variant is the toroidal or ring-type CT, which does not have a primary winding. Instead, the conductor carrying the current to be measured passes through the center of the CT. These are commonly used in switchgear and panelboards due to their compact design and ease of installation.

Safety is another critical consideration. Because CTs are connected to live circuits, improper handling can pose significant risks. It is essential to follow best practices, such as shorting the secondary winding when not in use, to prevent dangerous voltage spikes.

The Future of CT Current Transformers

As the demand for smarter and more efficient electrical systems grows, so too does the role of CTs. Advances in materials and design are enabling the development of more compact, accurate, and versatile CTs. Additionally, the integration of digital technologies is opening new possibilities for remote monitoring and data analysis.

For instance, smart CTs equipped with communication capabilities can transmit real-time data to centralized systems, enabling predictive maintenance and enhancing grid reliability. As renewable energy sources like solar and wind become more prevalent, CTs will play a vital role in integrating these intermittent sources into the grid.

Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >> Voir plus >>

Voir plus >>